Introduction

Cornflakes are a ready-to-eat, packaged cereal product. It is a favorite breakfast for people around the world. Cornflakes are a processed food and easily digestible.

Most cornflakes are made with added sugar and other flavors; hence, you can mix them with milk and consume them. Some brands of cornflakes may have minimum sugar, and the option of adding more sugar is left to the consumers.

Do you know how cornflakes are made? It is interesting to learn how a corn cob from the field is transformed into delicious ready-to-eat cornflakes. This article discusses how cornflakes are made and how cornflakes are made step-by-step.

As per the internet sources, the cornflakes were accidentally invented by the Kellogg brothers of the United States in 1890. They were making a dough for bread and left it over by mistake. The leftover dough turned into wheat flakes and tasted good when toasted. This inspired the Kellogg brothers to experiment with flakes of various grains including corn and rice.

Initially, the cornflakes made by the Kellogg brothers were bland and meant to a health food for patients. However, during the later period corn flakes was added with sugar, vitamins, and other ingredients to make it popular and more palatable to the people.

The selection of quality corn cobs from the field is an important step for getting good-quality cornflakes. The corn selection is made based on criteria like moisture content, kernel size, and overall quality.

Corn is also called maize. Corn is the name used in North American English and maize is used in British English.

How cornflakes are made

Freshly harvested corn cobs are selected based on their moisture content, kernel size, and overall quality. Corn kernels are extracted from the cobs. The kernels are cleaned, and only good-quality kernels are selected for further processing.

The selected kernels are cooked in industrial cookers for several hours to soften them. These kernels are milled and reduced to smaller grits to form a homogeneous dough.

The corn dough moves through a separation process to remove the husk and unwanted particles. This makes the corn dough smoother with a uniform texture.

The corn dough is mixed with ingredients like sugar, malt, salt, vitamins, and flavors. The dough is heated in steam to make it malleable.

This dough can be converted into cornflakes by two methods:

- Extruded cornflakes

- Rolled cornflakes

The corn dough used for rolled flakes contains bigger grits of corn kernel.

The cornflakes made by the above methods are further sprayed with hot sugar syrup and other additions. The cornflakes are roasted in hot air and cooled to make them dry and crisp. The dry and crisp cornflakes are inspected and the approved batch moves to packing.

Extruded corn flakes

The corn dough is forced through specific shaped dies and the knives at the end of the extruder cut the extruded corn flakes into the required shape and size. The cornflakes move to the next process.

Rolled cornflakes

The corn dough for rolled cornflakes contains bigger corn particles. The size of each particle can be 1/3 or 1/2 of the kernel size. The corn dough is passed between heavy steel rollers rotating in opposite directions. The tremendous pressure applied to the corn dough presses the corn grits into flakes. The cornflakes move to the next process.

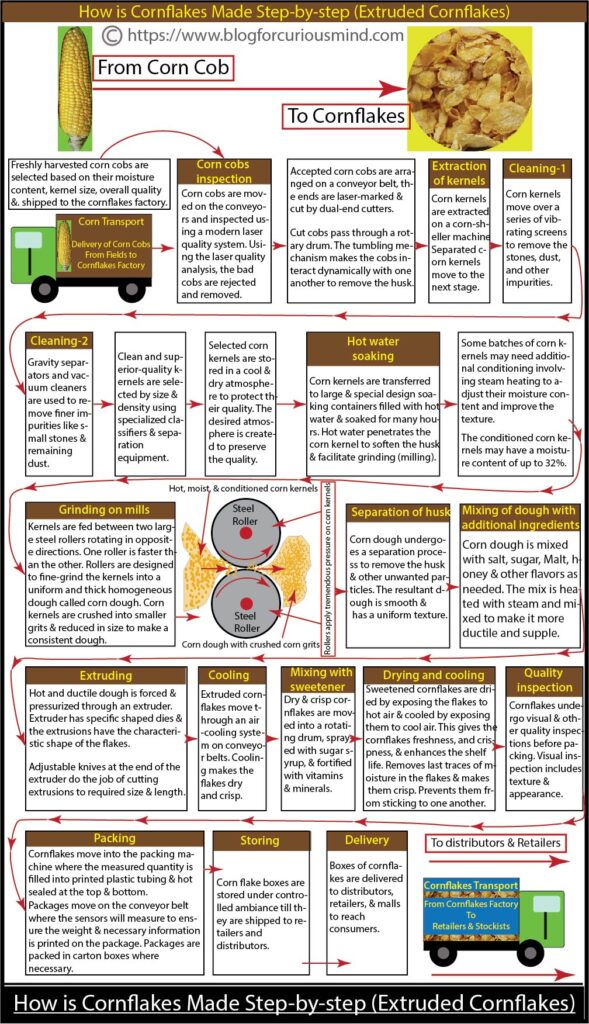

How are cornflakes made step-by-step (Extruded cornflakes)

Step 1

Freshly harvested corn cobs are selected based on their moisture content, kernel size, and overall quality. It is shipped to the cornflakes factory.

Step 2

The corn cobs are moved on the conveyors and inspected using a modern laser quality system. The laser system scans them for surface imperfections, color variations, and other defects. Using the laser quality analysis, the bad cobs are rejected and removed.

Step 3

The accepted corn cobs are arranged on a conveyor belt. As the conveyor moves, the ends of the cob are laser-marked and cut by dual-end cutters.

The cut cobs pass through a rotary drum. The tumbling mechanism in the drum makes the cobs interact dynamically with one another to remove the husk.

Step 4 Corn shelling machine

Corn kernels are extracted on a corn-sheller machine. This machine has special blades to detach the corn kernels from the cob. The separated corn kernels move to the next stage.

Step 5 First stage cleaning

The corn kernels move over a series of vibrating screens. The screens remove the stones, dust, and other impurities and retain the clean kernels.

Step 6 Second stage cleaning

Gravity separators and vacuum cleaners are used to remove finer impurities like small stones and remaining dust.

Step 7 Selection of top-quality corn kernels

Clean and superior-quality kernels are selected by size and density using specialized classifiers and separation equipment. This ensures that only top-quality corn kernels are used for corn flake production.

Step 8

The selected corn kernels are stored in a cool and dry atmosphere to protect their quality. The desired atmosphere is created to preserve the quality. When necessary, the corn kernels undergo a specialized moistening process to facilitate the softening of the corn husk and flake extraction.

Step 9 soaking and conditioning process

Corn kernels are transferred to large and special design soaking containers filled with hot water. The corn kernels are soaked in hot water for a specified time which can be many hours. The hot water penetrates the corn kernel to soften the husk and facilitate grinding (milling).

Step 10 additional conditioning

Some batches of corn kernels may need additional conditioning involving steam heating to adjust their moisture content and improve the texture. It helps better the separation of husk during the grinding stage and uniform cornflakes.

The conditioned corn kernels may have a moisture content of up to 32%.

Step 11 Grinding on mills

The kernels are fed between two large steel rollers rotating in opposite directions. The speed of one roller will be faster than the other. The rollers are designed to fine-grind the kernels into a uniform and thick homogeneous dough called corn dough. During grinding the corn kernels are crushed into smaller grits and reduced in size to make a consistent dough.

Step 12 Separation of husk

The corn dough undergoes a separation process to remove the husk and other unwanted particles. This makes the corn dough smoother with a uniform texture. The resultant dough is smooth and has a uniform texture.

Step 13 Mixing of dough with additional ingredients

The corn dough is mixed with salt, sugar, malt, honey, and other flavors as needed. The mix is heated with steam and mixed to make it more ductile and supple.

Step 14 Extruding

The hot and ductile dough is forced and pressurized through an extruder. The extruder has specific shaped dies and the extrusions have the characteristic shape of the flakes.

The adjustable knives at the end of the extruder do the job of cutting the extrusions to the required size and length.

Step 15 Cooling

The extruded cornflakes move through an air-cooling system on conveyor belts. The flakes get cooled rapidly and solidify. Cooling makes the flakes dry and crisp.

Step 16 Mixing with sweetener

The dry and crisp cornflakes are moved into a rotating drum, sprayed with sugar syrup, and fortified with vitamins and minerals.

Step 17 Drying and cooling

The sweetened cornflakes are dried by exposing the flakes to hot air and cooled by exposing them to cool air. This gives the cornflakes freshness, and crispness, and enhances the shelf life. This removes the last traces of moisture in the flakes and makes them crisp. Cooling the flakes prevents them from sticking to one another.

Step 18 Quality inspection

The cornflakes undergo visual and other quality inspections before they move into packing. The visual inspection includes texture and appearance.

Step 19 Packing

The cornflakes move into the packing machine where the measured quantity is filled into printed plastic tubing and hot sealed at the top and bottom.

The packages move on the conveyor belt where the sensors will measure to ensure the weight and necessary information is printed on the package. The packages may be further packed in carton boxes where necessary.

Step 20 Storing

The corn flake boxes are stored under controlled ambiance till they are shipped to retailers and distributors.

Step 21 Delivery

Boxes of cornflakes are delivered to distributors, retailers, and malls to reach consumers.

You may view this and this YouTube videos.

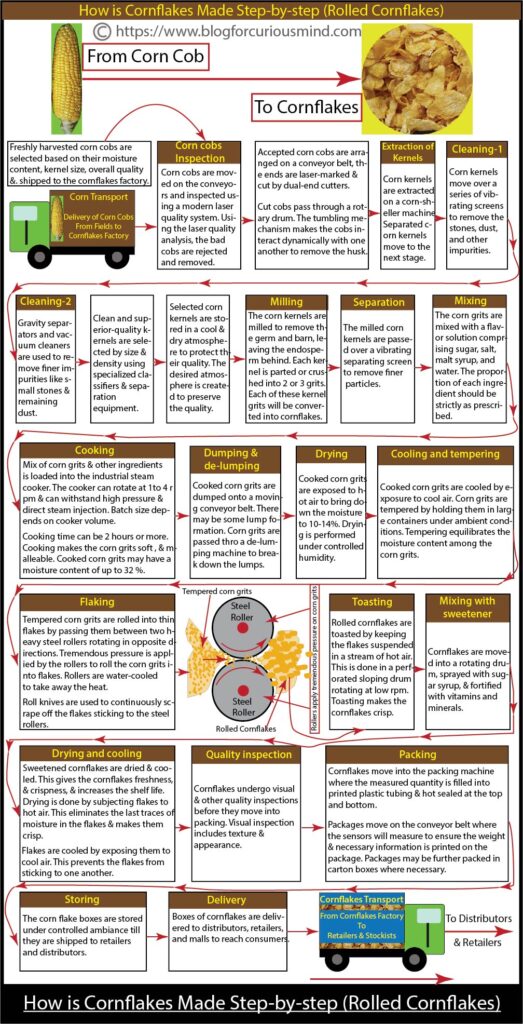

How are cornflakes made step-by-step (Rolled cornflakes)

Steps 1 to 8 are the same as above.

Step 8

The selected corn kernels are stored in a cool and dry atmosphere to protect their quality. The desired atmosphere is created to preserve the quality. When necessary, the corn kernels undergo a specialized moistening process to facilitate the softening of the corn husk and flake extraction.

Step 9 Milling

The corn kernels are milled to remove the germ and barn, leaving the endosperm behind. Each kernel is parted or crushed into two or three grits. Each of these kernel grits will be converted into cornflakes.

Step 10 Separation

The milled corn kernels are passed over a vibrating separating screen to remove finer particles.

Step 11 Mixing

The corn grits are mixed with a flavor solution comprising sugar, salt, malt syrup, and water. The proportion of each ingredient should be strictly as prescribed.

Step 12 Cooking

The mix of corn grits and other ingredients is loaded into the industrial steam cooker. The cooker can rotate at 1 to 4 rpm and can withstand high pressure and direct steam injection. The batch size depends on the volume of the cooker.

The cooking time can be two hours or more. Cooking makes the corn grits soft, and malleable. The cooked corn grits may have a moisture content of up to 32 %.

Step 13 Dumping and de-lumping

The cooked corn grits are dumped onto a moving conveyor belt. There may be some lump formation. The corn grits are passed through a de-lumping machine to break down the lumps.

Step 14 Drying

The cooked corn grits are exposed to hot air to bring down the moisture content to 10-14%. The drying is performed under controlled humidity.

Step 15 Cooling and tempering

The cooked corn grits are cooled by exposure to cool air. The corn grits are tempered by holding them in large containers under ambient conditions. Tempering equilibrates the moisture content among the corn grits.

Step 16 Flaking

The tempered corn grits are rolled into thin flakes by passing them between two heavy steel rollers rotating in opposite directions. Tremendous pressure (40 tons and above) is applied by the rollers to roll the corn grits into flakes. The rollers are water-cooled continuously to take away the heat.

Roll knives are used to continuously scrape off the flakes sticking to the steel rollers.

Step 17 Toasting

The rolled flakes are toasted by keeping the flakes suspended in a stream of hot air. This is done in a perforated sloping drum rotating at low rpm. Toasting makes the cornflakes crisp. Toasted cornflakes may have a moisture content of 1.5 to 3 percent.

Step 18 Mixing with sweetener

The cornflakes are moved into a rotating drum, sprayed with sugar syrup, and fortified with vitamins and minerals.

Step 19 Drying and cooling

The sweetened cornflakes are dried and cooled. This gives the cornflakes freshness, and crispness, and increases the shelf life. The drying is done by subjecting the flakes to hot air. This eliminates the last traces of moisture in the flakes and makes them crisp.

The flakes are cooled by exposing them to cool air. This prevents the flakes from sticking to one another.

Step 20 Quality inspection

The cornflakes undergo visual and other quality inspections before they move into packing. The visual inspection includes texture and appearance.

Step 21 Packing

The cornflakes move into the packing machine where the measured quantity is filled into printed plastic tubing and hot sealed at the top and bottom.

The packages move on the conveyor belt where the sensors will measure to ensure the weight and necessary information is printed on the package. The packages may be further packed in carton boxes where necessary.

Step 22 Storing

The corn flake boxes are stored under controlled ambiance till they are shipped to retailers and distributors.

Step 21 Delivery

Boxes of cornflakes are delivered to distributors, retailers, and malls to reach consumers.

You may view this YouTube video.

Conclusion

Corn flakes are a popular breakfast food all over the world. The reason for its popularity is it is ready to eat and tastes good. If you are new to cornflakes and want to add them to your diet, please consult your doctor before deciding. Do read the nutrient chart printed on the package. Despite the cornflakes manufacturers advertising it as a healthy food, corn flakes is a highly processed food and contains added sugar.

You may want to read the following articles:

How Poha is made from rice (paddy)

What is Sabudana and how it is made in India

How rice is grown and harvested in India

References

https://en.wikipedia.org/wiki/Corn_flakes

https://www.discoveryuk.com/how-its-made/how-corn-flakes-are-made